|

y

|

These plots resulted from twin Hall effect sensors configured to generate a transient at the start and at the completion of the Meissner transition. As can be seen, both mixes make the transition to a superconductive state across about 8 degrees Kelvin. This is consistent with published data on Bi-2223. Normally, industrial grade BSCCO begins its Meissner transition at 108K and is fully superconductive by 100K. This pellet was of slightly lower quality after being in storage for some years. A number of tests were performed using this configuration. Then those plots with the highest and lowest Tc's were discarded and the remaining 3 from each group were evaluated. Powder from the same BSCCO disk was used in all the tests. The average Tc improvement was found to be around 15 degrees. And the point at which diamagnetism first appears improved by an average of 20 degrees. This is the mysterious "pseudogap" region where electrons begin to pair up. See the below zoomed plots.

|

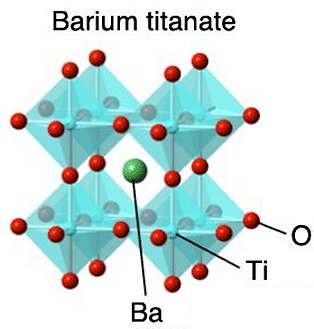

In the below test BTO was laminated onto both sides of a second BSCCO disk and direct resistance tests were performed. The results are comparable to the mix tests. Resistance begins to drop at the temperature where diamagnetism began to appear in the magnetization tests. Then the resistance curve flattens near where the Meissner transition begins.

NOTE: The Hall effect sensors employed do not generate a magnetic field. They operate within the 0.55 - 0.60 Oe ambient field from earth's magnetic field. So it is not known how strong a magnetic field the inverse proximity effect will exclude before quenching. Additional tests will need to be performed. Nonetheless, the 15 degree improvement in Tc confirms the correlation between permittivity and Tc is indeed real and could be exploited.

E. Joe Eck

© 2025 Superconductors.ORG

All rights reserved.

BACK to "News" page at Superconductors.ORG

BACK to "News" page at Superconductors.ORG